Air transport is forecast to be worth $193 billion and ship 57.7 million metric tons of cargo in 2023.

Theft, geopolitical friction, industrial action, the disjointed EU PLACI rollout, and more are affecting supply chain points across the world, causing disruption. For global life sciences logistics, careful planning is needed to safeguard product shipments.

Air transport in the life sciences industry

Leaders in life sciences depend on the expertise of air transport workers to ship medical products quickly and efficiently wherever they are most needed. Pharmaceutical and life science products being shipped between continents account for $2.5 billion in air cargo revenue each year, according to the International Air Transportation Association (IATA).

Air transport offers distinct advantages for the life sciences industry, including:

- Uninterrupted journey over any terrain

- High standard of security due to strict airport safety regulations

- Reliable delivery in regions not accessible by other transportation channels

- Emergency travel options when other types of transport are halted due to flooding and natural disasters

That doesn’t mean that air transport is without disruption, however.

As flights are often the only option to deliver temperature-sensitive materials in a timely manner, it’s in the interest of all life science stakeholders to understand and adapt to the challenges associated with airline disruptions.

Challenges with global life science logistics

1. Staffing shortages and industrial action

Staffing shortages plagued many major industries during the pandemic, including healthcare, education and transportation. Unfortunately, the air transportation industry was already beginning to grapple with a shortage of skilled workers before COVID-19 disruptions and continues to face them now.

The industry is also facing a swathe of industrial action from airport staff, especially cargo/baggage handlers. If negotiations don’t go smoothly, there will be major disruptions to flights worldwide.

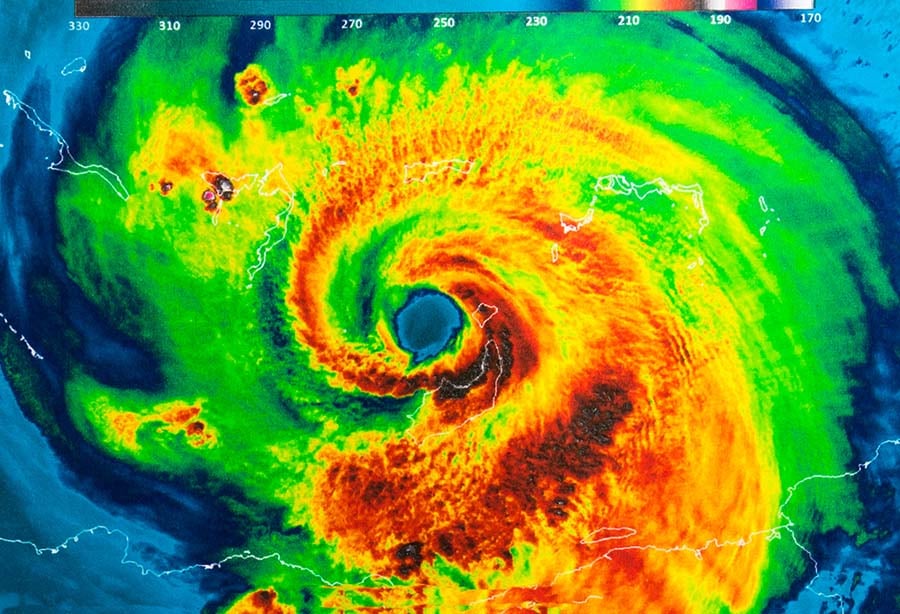

2. Extreme weather events

Climate change increases the frequency of extreme weather patterns, posing a threat to supply chains, and consequently, the life sciences industry. Hurricanes, rising sea levels and other extreme weather events will continue to have far-reaching impacts.

Modern supply chains often consist of thousands of suppliers located in multiple countries around the world. These complex supply chains depend on an efficient transportation network to move shipments along various routes to reach their final destinations. When even one region is impacted by a natural disaster, air transport suffers.

In many countries, communities may lack the resources from government agencies to respond to a crisis. Without adequate support to manage and restore vital infrastructure, re-routing supplies is required, causing further delays.

For example, a tornado in North Carolina damaged a Pfizer factory in 2023. It caused a shortage of dozens of drugs used in hospitals.

3. Geopolitical events

The war between Russia and Ukraine has caused supply shortages and price increases of oil, food and more. A year after Russia's invasion of Ukraine, jet fuel in Europe was a third more expensive than in 2019, when the airline industry last operated at normal capacity.

4. Compliance

Changes to regulatory compliance can cause disruption. The launch of the EU’s Pre-Loading Advance Cargo Information (PLACI) system in March 2023 sparked warnings from the International Air Transport Association (IATA) because the roll out was deemed “disjointed”. There were warnings that delays were predicted at customs while borders adjusted to the change.

Solutions to reduce supply chain disruptions

It’s crucial to address supply chain weaknesses by learning from past experiences and regularly reviewing processes. Numerous global life science logistics companies are tightening up their processes, adopting new technologies, collaborating to mitigate as much risk as possible.

Here are some key areas of discussion among air transportation, supply chain and regulatory leaders:

- Early communication between life science companies and manufacturers, suppliers, and third-party logistics coordinators is key to predicting air cargo availability and adapting to real-time disruptions.

- Transparency and flexibility between life science companies, logistics coordinators and airlines helps to avoid and solve complications quickly.

- Having comprehensive contingency plans, like chartered flights, reduces the impact of uncontrollable external factors on supply chains.

- Choosing logistics experts with specialist experience who have a proven track record in the industry typically have trusted supply chain partners who ensure the best shipping route.

- It is important to get the packaging right the first time for life science materials, as they are often irreplaceable. Paying for premium packaging like cold chain can make all the difference.

- Integrating monitoring and AI technology into supply chains will be critical for navigating future disruptions.

- Moving to more sustainable practices is vital for the environment, customers, and regulatory bodies who are demanding a shift. These shifts will take serious investment, but many leaders believe the alternative is unacceptable.

Master your global life sciences logistics

Preserve the lifetime of your products and reliability of deliveries with a logistics partner you can trust. Learn how we can comprehensively manage your logistics.

John Vanderneut

New York Operations Manager

John joined Biocair's New York team in 2016. He brings 40+ years of experience working in the airfreight and trucking industries at the John F. Kennedy International Airport.