The Puzzle

Ever wondered why you sometimes see temperatures reaching as low as -90.C in some of your shipments containing dry ice? It’s a question that has been often asked by many specialist courier companies and customers alike. Suggested causes from the dry ice producers and packaging manufacturers have included sub-standard dry ice which has a lower sublimation temperature, or pressure in the aircraft hold at 36,000 feet during the flight. However, it is neither of these.

The Answer

After much investigation, Biocair analysed the location of the package in transit versus the excursion time and realised the drops to -90.C were also happening while the shipment was on the ground, which ruled out the ‘pressure at high altitude’ theory. Biocair also trialled dry ice from different manufacturers, but the drops to -90.C were not particular to one supplier, which ruled out faulty or sub-standard dry ice.

Trialling different orientations of dry ice packaging

It was only when Biocair trialled different orientations of the packaging (upright, upside down, on its side) that we discovered the root-cause! When a box containing dry ice is turned on its side, we noticed the temperature drops to -90.C on the temperature monitor downloads, which coincided with the exact time the box was turned on its side. When the box was turned upright again, the temperature rises back up to -78.5C. When turned on its side again, it once again falls to -90.C.

We believe the reason this happens is; when the box is upright in its normal position, there is a layer of CO2 gas on top of the dry ice and the oxygen ingressing into the box through the seams of the lid is above the height of the dry ice and the layer of CO2 gas. Therefore, the CO2 gas acts as a buffer between the dry ice and the oxygen and slows down the sublimation / keeps the dry ice at its normal temperature of -78.5C. The lid of the polystyrene box is the only part of the box where oxygen travels in and CO2 escapes out. Turning or tipping the box onto its side, changes the lid from being on top, to being on the side. This now allows more oxygen in and more CO2 out and the oxygen can directly access the dry ice. As dry ice is endothermic, the increased rate of sublimation is what we believe causes the dry ice temperature to drop down to -90.C

In-house testing of dry ice packaging

To prove this theory is correct, we performed our own in-house test.

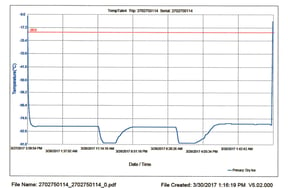

- On Day 1, we placed a dry ice temperature monitor inside a Biocair BC30 shipper box and filled it with dry ice, closed the lid and placed the box upright in its normal position.

- On Day 2 we tipped the box onto its side and left it there for several hours, before returning to its normal upright position.

- On Day 3 we repeated the same process again.

- On Day 4 we stopped the test and downloaded the temperature monitor. The results graph is shown below;

The Conclusion

These results prove our theory, that the reason why we sometimes see temperatures of -90.C in the temperature downloads from dry ice shipments, is due to the box being turned or tipped on its side, either intentionally or by accident, during transit.

Don Riach

Strategic Development Director

Biocair

If you have any questions regarding this article, please contact either Don Riach or your local Biocair office.