The pharmaceutical industry relies heavily on cold chain logistics to transport temperature-sensitive products such as vaccines and biologics. Ensuring the integrity and quality of these products during their journey from manufacturer to healthcare provider or patient is critical. Any temperature excursion or handling error can compromise the effectiveness of these products, leading to severe consequences for patient health and safety. This blog explores the importance of quality control in cold chain logistics for pharma products and how companies can maintain the required conditions throughout the transportation and storage process.

The Importance of Quality Control in Cold Chain Pharma Logistics

- Maintaining Product Integrity:

Pharmaceutical products such as vaccines and biologics are sensitive to temperature fluctuations. For example, vaccines often need to be stored and transported between 2°C and 8°C, while certain biologics and gene therapies may require cryogenic temperatures as low as -70°C. Exposing these products to temperatures outside their specified range can lead to degradation, loss of potency, and compromised efficacy. Effective quality control in cold chain logistics ensures that products are kept within the required temperature ranges, preserving their biological integrity.

- Adhering to Regulatory Requirements:

Pharmaceutical products are subject to stringent regulations set by authorities such as the FDA, EMA, and WHO. These regulations often include detailed requirements for temperature control during transportation and storage. For instance, Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP) require pharmaceutical companies to monitor and record the temperature of products throughout the supply chain. Quality control ensures that these regulatory standards are met, minimizing the risk of non-compliance and avoiding potential legal repercussions.

- Minimizing the Risk of Contamination and Damage:

The risk of contamination and damage to pharmaceutical products increases when temperature control is not properly maintained. Variations in temperature can alter the chemical composition of products or cause them to spoil, making them ineffective or dangerous. Additionally, poor handling practices, such as improper loading or unloading of temperature-sensitive goods, can lead to physical damage. By implementing quality control measures such as Standard Operating Procedures (SOPs), regular temperature monitoring, inspection of packaging integrity, and employee training, pharmaceutical companies can reduce these risks and ensure products are delivered in perfect condition.

- Ensuring Timely Delivery:

Timeliness is crucial in cold chain logistics, especially when dealing with life-saving medications. Delays in delivery can expose products to harmful conditions for extended periods, potentially causing temperature excursions that compromise product quality. Quality control ensures that products are delivered on time and in the right condition. By using advanced tracking systems and having contingency plans in place for unexpected disruptions, companies can minimize delays and maintain the required temperature control throughout the supply chain.

Key Quality Control Measures for Cold Chain Pharma Logistics

- Temperature Monitoring and Data Logging:

Continuous temperature monitoring is critical for maintaining the integrity of pharmaceutical products. Real-time sensors, RFID tags, and data loggers track temperature fluctuations and alert teams to deviations. This ensures compliance with regulations and provides an audit trail of temperature conditions throughout the supply chain.

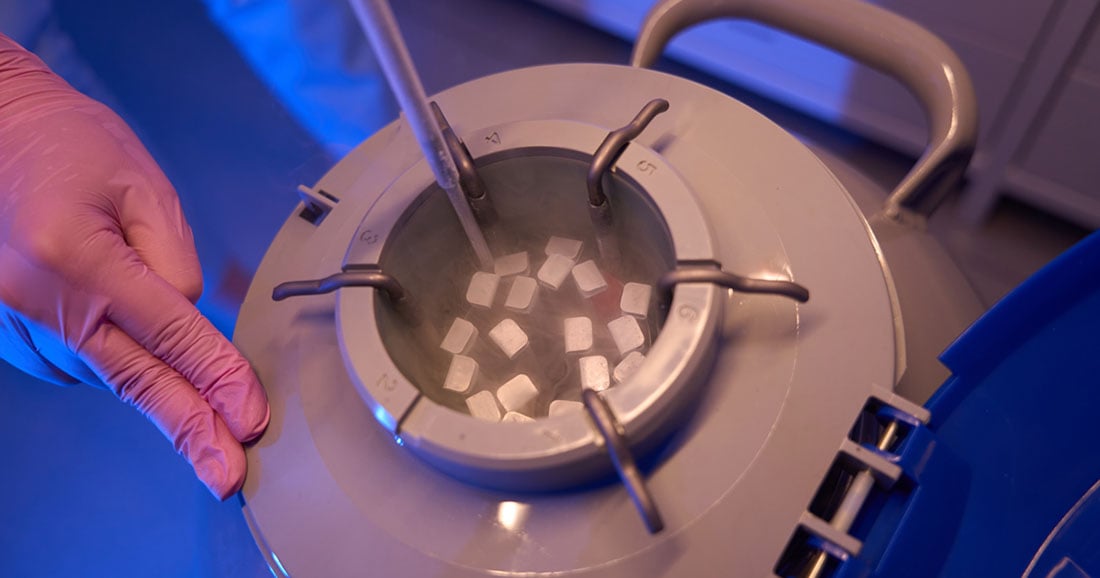

- Packaging Solutions:

Advanced packaging, such as liquid nitrogen dewars, maintains the required temperature during transport. Packaging must be durable to protect products and ensure the temperature control system remains effective throughout transit.

- Regular Audits and Inspections:

Routine audits of storage facilities and transportation vehicles ensure proper cold chain functionality. Regular checks help identify potential issues before they cause temperature excursions or product damage.

- Employee Training and Awareness:

Proper employee training is essential for maintaining quality control. Employees must be familiar with best practices for handling, storing, and transporting temperature-sensitive products, including emergency response procedures.

- Contingency Plans:

Contingency plans are crucial for dealing with disruptions, such as weather delays or equipment failures. These plans include backup power, alternative routes, and additional cooling systems to ensure products remain protected during emergencies.

Conclusion

Quality control in cold chain logistics is crucial for the safe delivery of temperature-sensitive pharmaceutical products like vaccines, biologics, and gene therapies. Even minor temperature fluctuations can compromise product efficacy. By employing advanced temperature monitoring, packaging solutions, and comprehensive employee training, pharmaceutical companies can ensure product integrity and regulatory compliance. Ultimately, robust quality control ensures life-saving products arrive in optimal condition, supporting better patient outcomes globally.

Key Takeaways:

- Cold chain logistics is critical for the safe transport of temperature-sensitive pharmaceutical products.

- Effective quality control ensures product integrity, regulatory compliance, and minimizes risks of contamination or damage.

- Temperature monitoring, high-quality packaging, regular audits, and employee training are essential components of cold chain quality control.

- Timely delivery of pharmaceutical products is critical, and contingency plans are necessary to address potential disruptions.

Related Contents:

Biocair

Cold Chain Solutions for Life Sciences and Pharma

Biocair is a global logistics provider specializing in pharmaceutical, biotechnology and life sciences supply chain solutions with nearly 40 years of experience. By assembling a team of best-in-class industry experts in quality, cold chain and regulatory compliance, Biocair focuses on providing the most comprehensive time-sensitive and temperature-controlled solutions.